Investment in New Machinery

Moduflex recognises that the only way to stay ahead of the competition is to be responsive to client demands for new and interesting products, whilst keeping an eye on market forces.

This has led to an investment in product design technology, new staff, new software and new machinery. We intend to continue to manufacture heritage products to the highest possible standard, whilst introducing new products for our customers as and when required.

Moduflex has invested heavily in new machinery, and therefore manufacturing capacity in recent years. The investment has led to the in-house manufacture of MFC products, expanding our personnel, improved production times, and extending our overall product portfolio.

A significant percentage of components for our mobile systems have been manufactured externally in the past, but we now have the capabilities to manufacture these in-house. Our raw materials are also sourced from within the UK to minimise our carbon footprint. Our raw steel is made from 80% recycled content and our MFC is 50%.

We’ve implemented Lights-Out manufacturing, meaning our CNC machines can run at night without human intervention, meaning fewer hours of lighting is needed to run the machines.

Keep reading below to discover some of the latest machinery we’ve invested in.

Salvagnini P1 Panel Bender

This machine has replaced our previous factory process of bending sheets of steel by hand with a press brake machine, and re-tooling for different metal thicknesses which was very manual and time consuming.

This powerful new equipment automatically bends complex folds in the metal in seconds as seen in this video, without the need to change tools, leading to a much faster production time of our shelving products and a more precise finish.

Using sustainability technology, the bending formula automatically optimises the bending parameters to reduce material waste.

FLW - 2.0 Laser Welders

Last year, we invested in two new laser welders for our steel factory. Compared to traditional welding, the laser welder is extremely precise, meaning the surrounding metal is not warped, and creating much deeper welds for a stronger and cleaner final product.

The laser welder has dramatically reduced the production time and improved the quality of our steel product range, which our customers have been thrilled with!

Amada MP SheetCat

This machine has significantly improved production speeds, being able to run without human intervention, automatically loading, unloading, and exchanging steel sheets onto our CNC machine for punching. It’s also fully electric meaning it can be powered with clean renewable energy from our solar panels.

Compact and Powerful HOLMZA HPP300 The proven base model of the 3 series, offers high performance in a compact design. Designed for smooth material flow and precise logistics, this machine is the workhorse of the MFC facility.

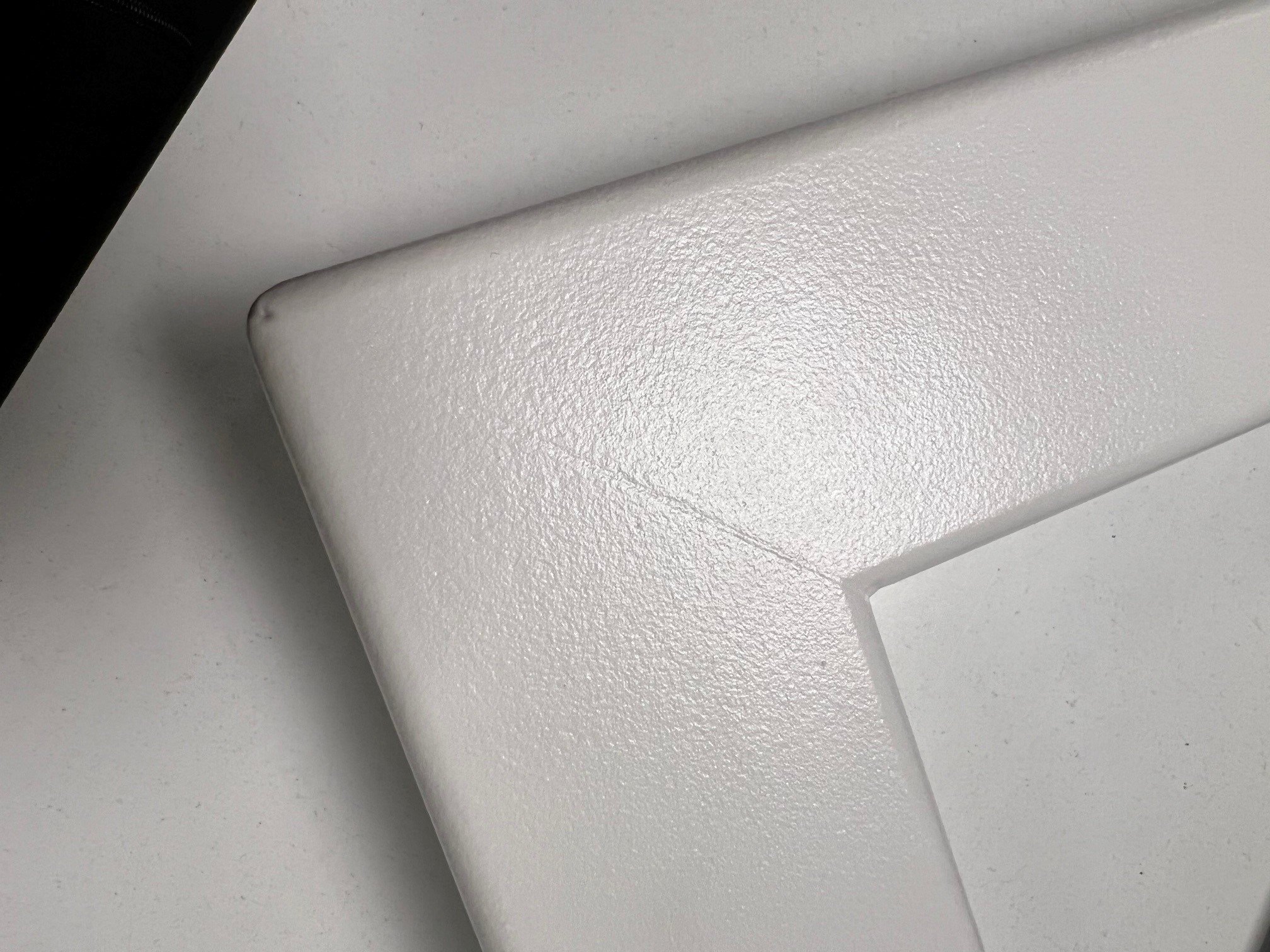

EDGETEC S-240 Our state-of-the-art Homag airTec machine uses compressed super-heated, high-velocity air to activate the adhesive layer. AirTec technology is a clean, cost effective bonding method that uses a combination of technically engineered hot air and special edge material to produce the ultimate invisible joint.

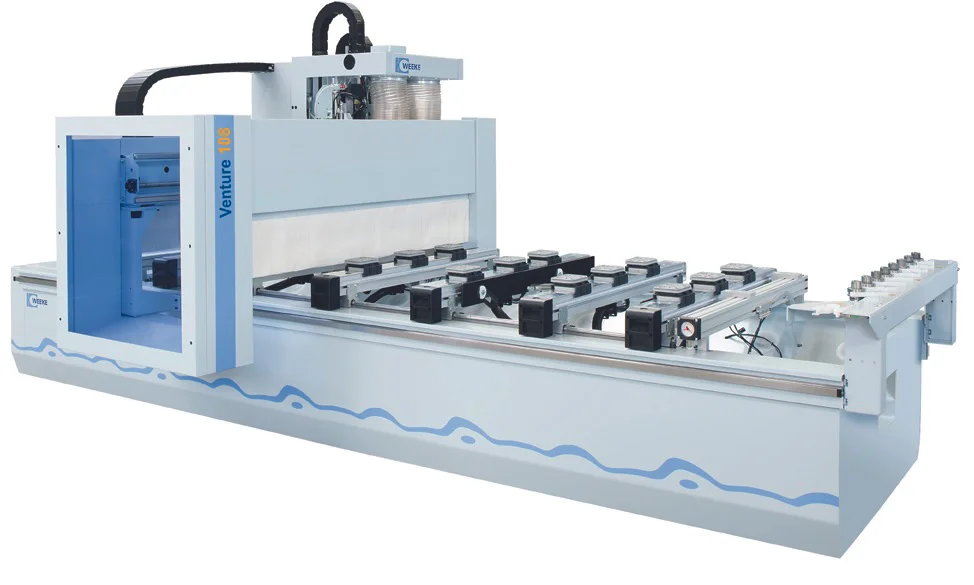

CNC Processing Centre WEEKE VENTURE 108 A versatile volume production machine designed for precision and scale. The touch screen GUI operation; improves accuracy, reduces prototyping, and processing time.